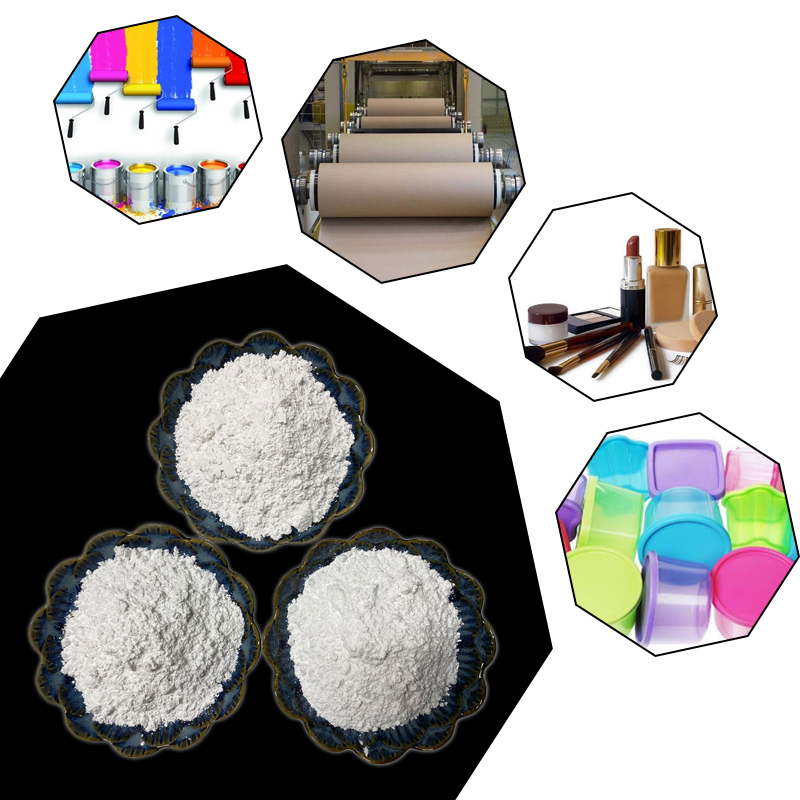

Talc Powder 1250mesh, Talc Powder Supplier High Purity Talcum Powder for Cosmetic

The main component of talc is magnesium silicate containing water, with the molecular formula Mg3 [Si4O10] (OH) 2. Talc belongs to the monoclinic system. The crystal is in the form of pseudo hexagonal or rhombic flakes, occasionally seen. Usually formed into dense clumps, leaf like, radial, and fibrous aggregates. Colorless transparent or white, but appearing light green, light yellow, light brown, or even light red due to the presence of a small amount of impurities; The cleavage surface shows a pearl luster. Hardness 1, specific gravity 2.7-2.8.

Talc has excellent physical and chemical properties such as lubricity, anti adhesion, flow aid, fire resistance, acid resistance, insulation, high melting point, inactive chemical properties, good covering power, softness, good luster, and strong adsorption. Due to its layered crystal structure, talc has a tendency to easily split into scales and special lubricity. If the content of Fe2O3 is high, it will reduce its insulation.

Talc is soft, with a Mohs hardness coefficient of 1-1.5 and a sliding sensation. The {001} cleavage is very complete, and it is easy to crack into thin slices. The natural resting angle is small (35 °~40 °), and it is extremely unstable. The surrounding rock is silicified and slippery magnesite, magnesite, lean ore, or dolomite marble. Except for a few moderately stable rocks, they are generally unstable, with developed joints and fractures. The physical and mechanical properties of the ore and surrounding rock have a significant impact on the mining process.

Chemical grade

Usage: Used as a reinforcing and modifying filler in chemical industries such as rubber, plastics, paint, etc. Features: Increase the stability of product shape, increase tensile strength, shear strength, winding strength, pressure strength, reduce deformation, elongation, thermal expansion coefficient, high whiteness, and strong particle size uniformity and dispersion.

Ceramic grade

Usage: Used for manufacturing high-frequency ceramics, wireless ceramics, various industrial ceramics, architectural ceramics, daily ceramics, and ceramic glazes. Features: High temperature non discoloration, enhanced whiteness after forging, uniform density, good luster, and smooth surface

Cosmetic grade

Purpose: It is a high-quality filling agent in the cosmetics industry. Features: Contains a large amount of silicon element. It has the function of blocking infrared rays, thereby enhancing the sunscreen and infrared resistance performance of cosmetics.

Medical and food grade

Usage: Used as an additive in the pharmaceutical and food industries. Features: It is non-toxic, odorless, with high whiteness, good compatibility, strong glossiness, soft taste, and strong smoothness. A pH value of 7-9 does not degrade the characteristics of the original product.

Paper grade

Purpose: Used for various high and low grade paper industry products. Characteristics: Paper powder has the characteristics of high whiteness, stable particle size, and low wear. The paper made with this powder can achieve smoothness, delicacy, save raw materials, and improve the service life of the resin mesh.

Brucite powder

Usage: Used for manufacturing electric porcelain, wireless electric porcelain, various industrial ceramics, architectural ceramics, daily ceramics, and ceramic glaze. Features: High temperature non discoloration, enhanced whiteness after forging, uniform density, good glossiness, and smooth surface.